Fuel Tank Cleaning & Fuel Restoration

Dirt and sludge in your tanks is a hidden enemy putting not only your people at risk, but can jeopardise your fleet.

International research reveals over 36% of bulk fuel storage tanks contain destructive contaminants on the tank floor. In Africa, this number climbs to over 45%. Affecting underground and surface mounted tanks, these bacterial or corrosion related contaminations can lead to catastrophic asset failure in machines or pumping equipment.

Remove the Risk of damaging your FLEET Assets

Fueling your costly, sophisticated yellow fleet with contaminated fuels today comes with higher risk than ever before. Let the Petromonitor process reduce your filter cartridge usage AND safeguard your assets simultaneously.

Patented Cleaning System

Sampling Pre and Post Clean

Least Waste Process

Restores Fuel to Refinery Standards

Unique and Advanced Cleaning Process

Removes 100% of microbial growth from diesel.

Patented Quality Process

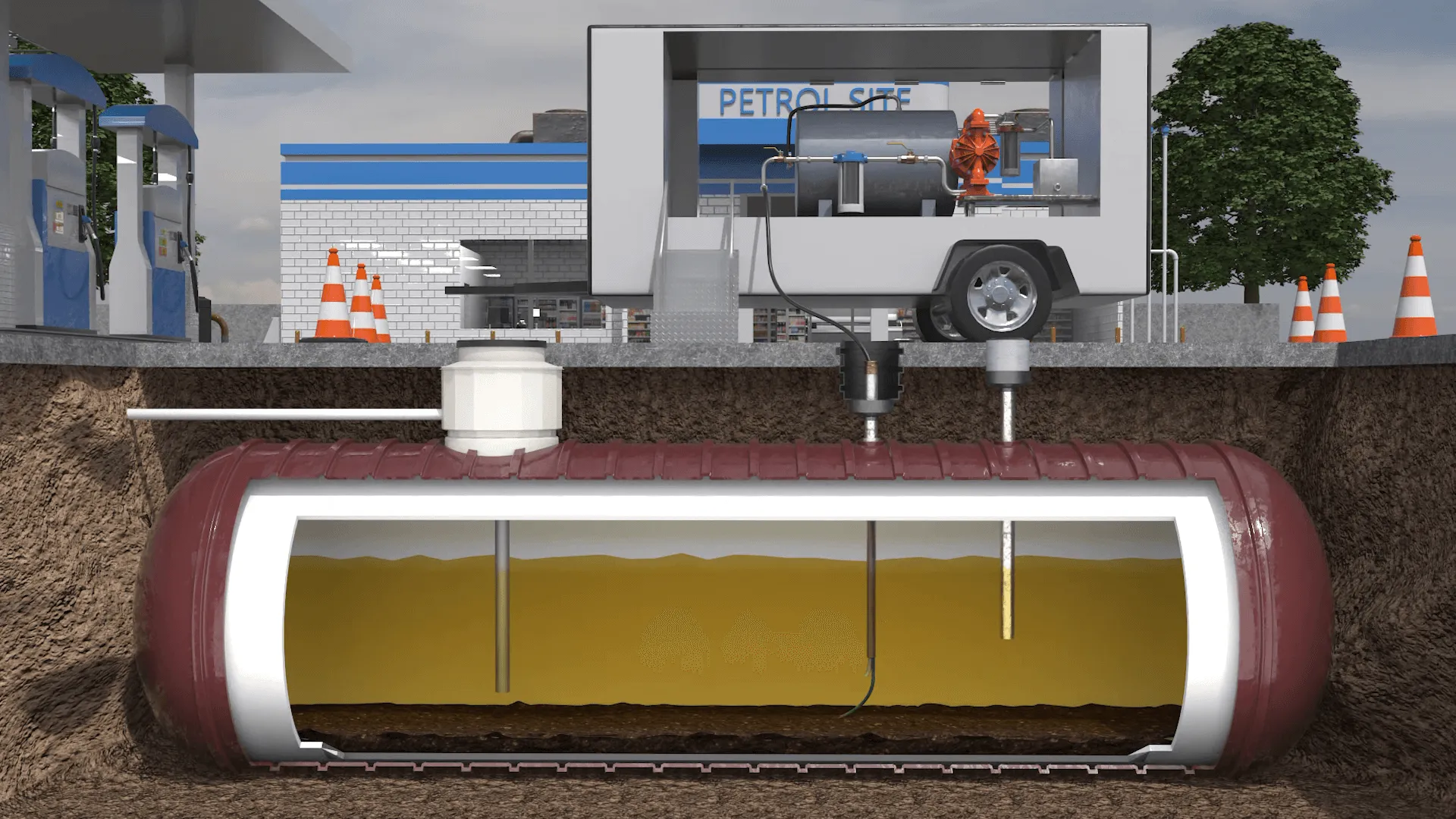

The patented fuel polishing and tank cleaning process used by Petromonitor is a methodical and systematic process proven to be the most advanced in the industry. Trusted by major networks across the globe, our system is able to remove free water, dirt and sludge from the tank floor, repair dangerous phase-separation and remove an absolute minimum of fuel from your site in the process.

Free Water Removal

Phase Separation Remediation

Minimal Product Loss

Tank Floor Clean

Try out our tank-clean calculator to help you with budgets!

Drop in your tank numbers under the various tank size checkboxes and calculate how far your site is from our base in Vereeniging to get your total.

The Cleaning Process

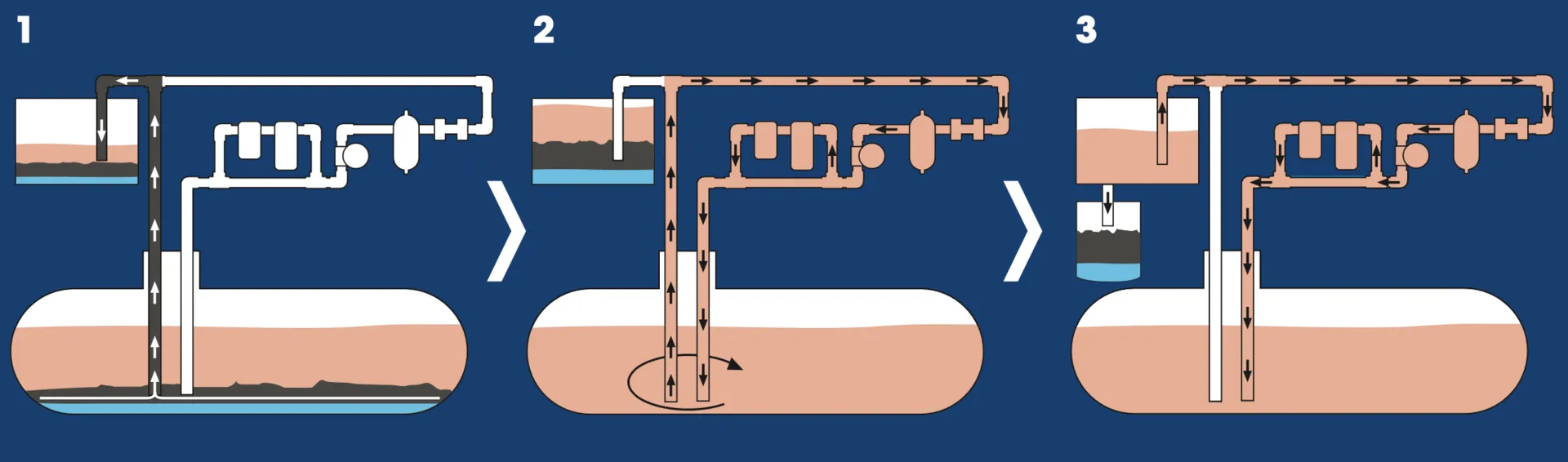

Step 1

Removal of water and contaminants such as rust particulate, bacterial sludge and foreign matter. Equipment traverses the entire tank floor from multiple access points and solids are pumped into a holding tank. This is left to to settle for the duration of Step 2.

Step 2

We then circulate the fuel in the contaminated tank through our filtration system. Conditioning, filtration and polishing of the fuel to 4 micron, passing through a coalescer and magnetic conditioner. This fuel is 100% suitable for sale to your customers or used in your fleet.

Step 3

Remaining fuel in the settlement tank is filtered and returned to the underground tank and waste disposed of in accordance with local regulations. Less fuel is carried off site than any other cleaning method.

How it works

While competitors claim to clean tanks, most fall short of providing a rounded solution. Petromonitor's first priority is safety. Our work site is fully barricaded but also allows the site to remain fully operational.

Samples are taken at the start after which the 3 step process follows:

Step 1 involves vacuuming the tank floor to remove sediment and sludge which is stored separately for disposal later.

Step 2 circulates your fuel using transparent hoses through a coalescer, filtration banks (4 Micron) and magnetic conditioning filter.

Step 3 Remaining fuel in the settlement tank is filtered and returned to the underground tank and waste disposed of in accordance with local regulations

Watch a demo of our tank cleaning and fuel restoration process

Petromonitor provides the most comprehensive solution for removing contamination and free water as well as a patented process for restoring fuel quality and remediating phase separation in underground fuel storage tanks.